Committed to quality, reliability and keeping ourselves ahead of the competition, our design and development teams utilise computer hardware and software support options to meet any standard or special client needs.

Furthermore, our staff are trained in the use of CADCAM for designing and integrating their works for CNC punching and forming. Let us know what you need, and we’ll get it done with professional, precision design and development.

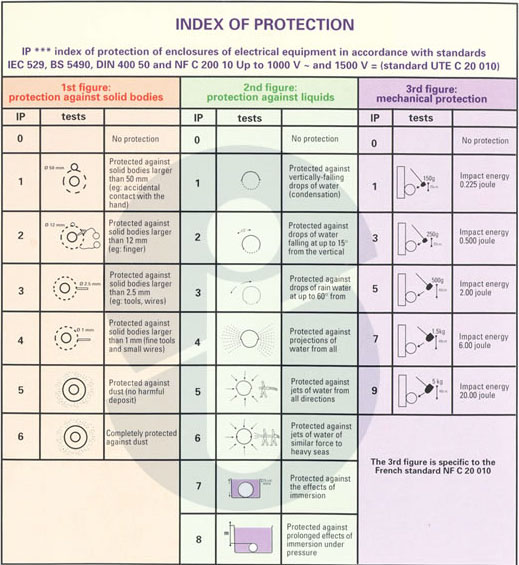

View necessary technical information here.

To service you more effectively, efficiently, and better than ever – we have invested in our very own 5,000 square metre floor area building, with our own warehousing, production, operations and logistics facilities.

With our industry-leading switchboard and electrical enclosure products, Spanners has been a trusted brand name, and leader in the Singapore market, for over 20 years now. During this time, we have also expanded our regional network to cover countries like Brunei, Thailand, Cambodia, Vietnam, Malaysia and Indonesia.

With one of the largest arrays of manufacturing equipment in the industry, we have the capacity to support a wide range of standard and custom fabrication requirement of today's industrial and commercial challenges.

Our primary fabrication equipment includes:

Our operations also utilise:

Our assembly teams are trained to ensure all assembly work meets requirements set, and expected by our clients.

As an ISO certified company, every product leaving our assembly line is put through stringent quality checks – so you can always be assured of consistently high quality products from us.

A look into the indoor installation of LT Boards.

Overhead cranes being used to unload LT Boards to substations within construction sites. |

LT Boards being hoisted into substations for installation. |

LT Boards are installed into their positions in the shortest possible time. |

LT Board panel being secured to the ground with anchor bolts. |

The final inspection, carried out after the LT Boards have been installed. |

A glimpse into an outdoor OG Box installation.

Precast concrete is individually customised to accommodate the excavated ground conditions. |

Our workers are trained to handle outdoor installations effectively, efficiently and safely. |

Adjustments are made, and a final check is carried out before the trenches are filled back in. |

After the concrete is firmly secured by the soil, the box is checked for levelness, before it is finally covered to ground level. |

2024 © Spanners International Pte Ltd.